Gps Antenna Welding

With the rapid development of Global Positioning system (GPS) technology, GPS antenna is more and more widely used in various fields. As the key equipment of receiving GPS signal, the performance of GPS antenna has an important influence on the positioning accuracy and application effect of GPS system. The welding technology of GPS antenna is one of the important factors affecting the performance of GPS antenna. This paper introduces the application and optimization method of GPS antenna welding technology.

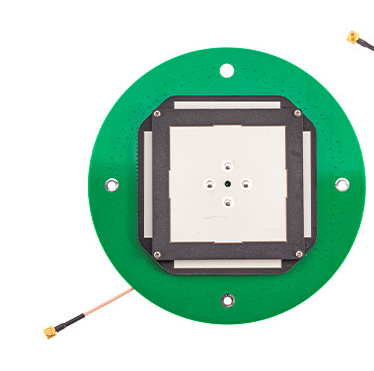

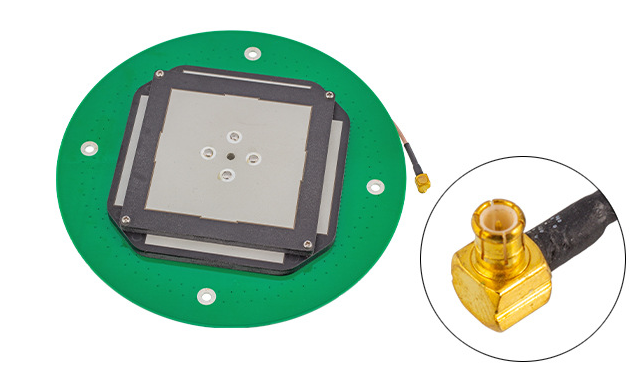

Overview of GPS Antenna

GPS antenna is an important part of GPS receiver, which is responsible for receiving signals from GPS satellite. Its performance is affected by many factors, such as antenna design, material, manufacturing technology and so on. Welding technology is a key link in the manufacturing process of GPS antenna, especially for the connection between antenna feed and antenna body, which is the core component of GPS antenna. Welding quality directly affects the performance and service life of GPS antenna.

Application of GPS Antenna Welding Technology

1. Selection of welding process.

In the manufacturing process of GPS antenna, the selection of welding process is very important. According to the characteristics of antenna material and structure, choose appropriate welding methods, such as manual arc welding, laser welding, resistance welding, etc., and consider the selection of welding materials to ensure welding quality.

2. Welding process control

In the process of GPS antenna welding, it is necessary to strictly control the welding parameters, such as welding current, voltage, welding speed, etc., to ensure the welding quality, and pay attention to the selection of welding environment to avoid the impact of environmental factors on the welding quality.

3. Welding quality inspection

After the completion of welding, the welding quality needs to be tested, and the commonly used testing methods include appearance inspection, X-ray inspection, ultrasonic inspection and so on. Through inspection, we can ensure that the welding quality meets the requirements and ensure the performance of the GPS antenna.

Optimization method of GPS Antenna Welding Technology

1. Improve welding materials

Through the development of new welding materials to improve the corrosion resistance and strength of the weld, so as to improve the service life of the GPS antenna.

2. Optimize the welding process

According to different types of GPS antennas, the welding process is studied and optimized to improve welding quality and efficiency. Automatic welding equipment is adopted to reduce the influence of human factors on welding quality.

3. Introduce advanced welding technology.

With the development of science and technology, many advanced welding technologies are gradually mature, such as laser welding, electron beam welding and so on. Applying these advanced technologies to the manufacturing process of GPS antenna can improve welding quality, production efficiency and product quality.

4. Strengthen process control

By strengthening the quality control of the welding process, ensuring the stability and reliability of each production link, establishing strict production processes and quality control standards, and monitoring and adjusting the key parameters in the production process in real time.

5. Improve the detection means.

With the development of testing technology, many advanced non-destructive testing technologies are gradually applied to the welding quality inspection of GPS antennas. Through the introduction of these advanced technologies, the testing accuracy and efficiency are improved and the product quality is ensured.

GPS antenna welding technology is a key link in the manufacturing process of GPS antenna. The performance and service life of GPS antenna can be improved by selecting appropriate welding process, optimizing welding materials, introducing advanced technology and strengthening process control. With the continuous progress of science and technology, GPS antenna welding technology will be further developed, which will provide strong support for the wide application of GPS system.